Further Information

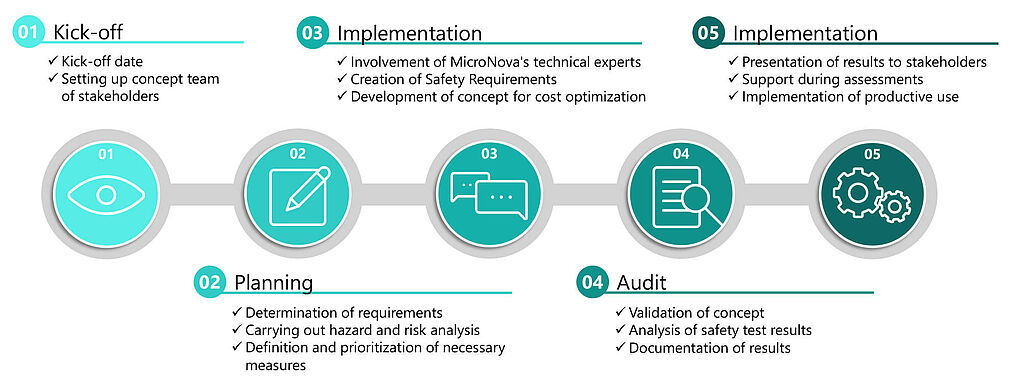

This is because MicroNova’s consulting services cover both the implementation of functional safety methods from the start of a project as well as their subsequent incorporation into projects that are already underway. The first step in this process is to identify the necessary requirements and create a corrective action plan. Our consultants then perform a hazard and risk analysis to identify the measures required and provide support for their practical implementation. This includes creating safety requirements and ensuring the traceability of test results based on these requirements. The relevant documentation is generated automatically as far as possible and serves as the groundwork for assessments and audits in accordance with the ISO 26262, ISO 21448 (SOTIF) and IEC 61508 standards.

Another area of focus of MicroNova Consulting is the qualification of tools and tool chains in accordance with ISO 26262, which has already been successfully completed in numerous customer projects. It initially involves identifying potential errors in the tool chain and defining suitable measures. In addition to the execution and assessment of tests, qualification also entails the preparation of classification and qualification reports as well as support during assessments.

ISO 26262 Qualification of Virtual ECU

The qualification of a so-called “virtual control unit” (vECU) in accordance with ISO 26262 was commissioned as part of the development of a highly available ECU. This is software designed to act as a replacement for the physical control unit.

Project content and applied methods

- Development of a concept for the implementation of qualification in accordance with ISO 26262

- Execution of qualification using the “tool validation” method

- Specification of the software subcomponents

- Specification of use cases for the software

- Error impact analysis for each use case

- Specification of the error detection and correction measures for each use case

- Evaluation of the results of test suites performed for the validation of the use cases

- Preparation of a classification report

- Preparation of a qualification report

ISO 26262 Qualification of Software Tool

The client company commissioned the qualification of a software tool in accordance with ISO 26262. ISO 26262 requires tests under normal operating conditions for the qualification of a software component, as well as tests adding errors to the system to check how it reacts to abnormal inputs. Software errors such as runtime and data errors are analyzed and corrected during the development process.

Project content and applied methods

- Concept for the performance of tool qualification in accordance with ISO 26262-8 (supporting processes)

- Gap analysis to ensure qualification is achieved

- Selection of the qualification method for the tool

- Performance of an FMEA

- Determination of tool impact, tool error detection, and tool confidence level

- Assurance of requirements traceability

- Preparation of a classification report

- Preparation of a qualification report

Functional Safety for Test Automation: EXAM ISO 26262 QKit

In addition to its extensive consulting services, MicroNova also offers products for qualification and certification in accordance with ISO 26262. The EXAM test automation solution has been extended accordingly: the “EXAM ISO 26262 QKit” plug-in uses a semi-automated approach to checking for compliance of the EXAM tooling with “ISO 26262 Part 8: Supporting processes, Chapter 11: Confidence in the use of software tools”.

The EXAM QKit can be used to integrate products or solutions relevant to ISO 26262 into the documentation of automotive OEMs or their suppliers. A report, plan, safety manual and a verification or validation report can be prepared for the classification – all in accordance with ISO 26262.

Use our experience to your advantage

MicroNova has many years of practical experience in their respective fields. Our consultants have direct access to our experts in hardware and software development as well as testing. With MicroNova you get not only consulting, but also the knowledge and experience from more than 30 years of automotive engineering.

Talk to us and find out how we can support you in your individual challenges!

MicroNova AG

Consulting

Unterfeldring 6

D-85256 Vierkirchen

Tel.: +49 8139 9300-0

Fax: +49 8139 9300-80

E-Mail: consulting@micronova.de