The NovaCarts HiL family of products boasts maximum modularity and scalability as well as a variety of networking options. Since this is true of all the hardware and software components used, MicroNova’s NovaCarts custom solutions also make it possible for automotive companies to have tailor-made applications developed for their current testing requirements. Our hardware and software development specialists create solutions for specific test scenarios.

NovaCarts Charger

The NovaCarts Charger (NC Charger) charge and discharge (CD) unit is used to monitor and control the charging and discharging of vehicle traction batteries, thereby assisting automotive manufacturers and suppliers with their battery transport and storage requirements. Specific precautions are necessary for safe transportation, as batteries are classified as dangerous goods under international transport law.

The NovaCarts Charger can be used to discharge batteries to a required state of charge (SoC) for transport (e.g. a maximum of 30 percent for air cargo). Furthermore, the NC Charger can be used to set the optimal SoC recommended by the manufacturer, which reliably prevents deep discharge.

The battery management system (BMS) is supplied with voltage and the necessary CAN messages in order to charge or discharge a battery. This is performed by means of what is known as residual bus simulation, which is adapted to the particular BMS. The compact device operates on the three-phase mains supply and can be deployed flexibly thanks to its wheeled design.

Further Information

- Datasheet: NovaCarts Charger

- Article: Safe Storage and Transportation of Batteries

Intelligent Breakout-Box (iBOB)

MicroNova has developed an intelligent breakout box for SPI buses (iBOB) specifically for testing the signals between two microcontrollers that communicate with each other via a serial peripheral interface. These are on the same board and monitor each other over a serial peripheral interface (SPI). The SPI signals can be specifically manipulated in order to test the behavior of both chips in the event of an error and to verify their error-handling algorithms.

In addition, the test solution is able to record not only the SPI communication but also all analog and digital signals of the hardware connected to the two microchips. One possible application is the testing of electronic control units (ECUs) for car brakes.

Further Information

- Datasheet: Intelligent Breakout-Box (iBOB)

- Reference ZF: iBOB: Intelligent Breakout Box for SPI Buses

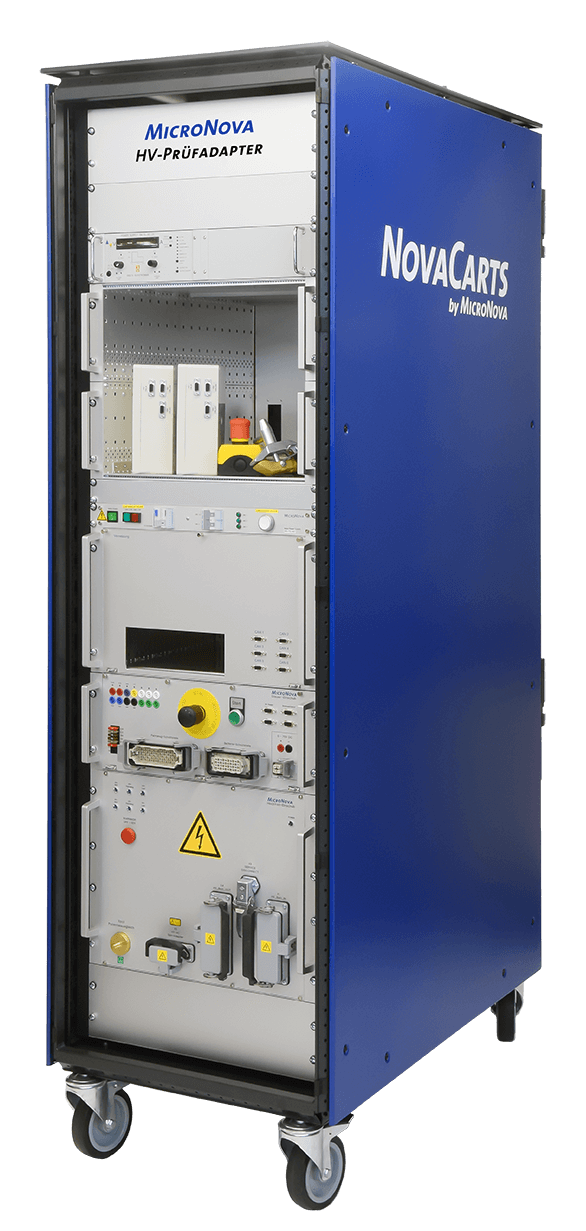

NovaCarts HV Test Adapter

The NovaCarts HV Test Adapter makes it possible to test the intrinsic safety of high-voltage (HV) systems in hybrid and electric vehicles. For this purpose, the system simulates typical operating conditions as well as extreme safety-critical cases where the vehicle control units have to react by shutting down, for example.

The HV test adapter can withstand real battery current between the battery and traction circuits in the vehicle and measures current and voltage in the DC link (battery side, load side, and external supply). In addition, it allows insulation resistance to be checked and the vehicle pilot line to be manipulated.

Moreover, the vehicle CAN bus can be logged and manipulated. Since the HV test adapter has its own hardware safety circuit, it can be safely operated in stand-alone mode as well as on a vehicle or traction battery test bench.